In November 2020, AEEE co-presented a model National Cooling Action Plan (NCAP) development framework at the 32nd Meeting of the Parties to the Montreal Protocol (MOP32), along with UNEP, UNESCAP, and other flagbearers of sustainable cooling practices. The NCAP development framework presents a model approach that encapsulates the shared experience of NCAP development teams the world over, including emerging economies and climate vulnerable countries such as the Caribbean countries, Rwanda, Kenya, China, Vietnam, Thailand, and India, demonstrating South-South Cooperation.

Harmonising energy efficiency with the refrigerant transition for integrated climate action is one of the key underlying themes of the NCAPs being developed under the aegis of the Montreal Protocol. An important question emerges: Why is the Montreal Protocol, an international treaty which has historically governed the production and consumption of ozone-depleting refrigerants (used as heat-exchanging fluids refrigeration and air-conditioning [RAC] cycles, among other uses), interested in energy efficiency?

The Refrigerant Transition

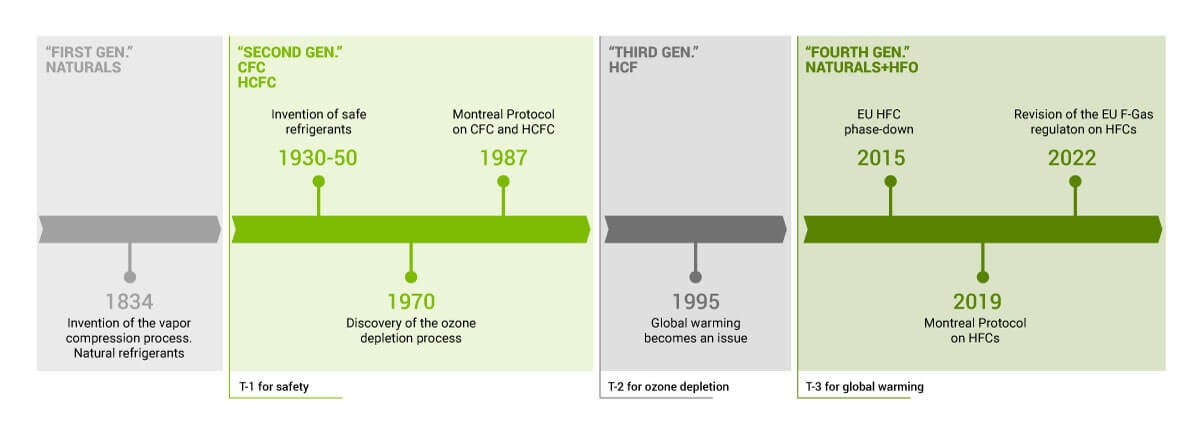

Let us take a step back to understand the four generations of refrigerants and the genesis of the Montreal Protocol (Figure 1). The first generation of refrigerants (or early refrigerants) was roughly used from 1835 to 1930 and included ammonia, propane, carbon dioxide, and sulphur dioxide. These compounds had good thermodynamic characteristics but were either toxic or flammable, which wasn’t suitable to scale up the refrigeration industry. Around 1930, there was a transition (T1) to the second generation of refrigerants dominated by chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) such as dichlorofluoromethane (R-21), trichlorofluoromethane (R-11), and R-22 (HCFC). It is then that many advancements and amendments to the most widely recognised safety standard by ASHRAE (ASHRAE Standard 15) was made. By the 1980s CFCs and HCFCs were used not only as refrigerants but as foam-blowing agents, cleaning solvents, and aerosol propellants for personal care products. It is also around the same time that CFCs were linked to the destruction of the ozone layer – this discovery led to the second transition of refrigerants (T2) from CFCs, and subsequently even HCFCs, to hydrofluorocarbons (HFCs). The second and subsequent refrigerant transitions were governed by the Montreal Protocol of 1987.

The Montreal Protocol was (and still is) a landmark multilateral environmental agreement. It has undergone multiple iterations, the latest of which was the Kigali Amendment of 2016. A directional shift took place at Kigali – the Montreal Protocol would now focus on controlling not just ozone depletion but global warming also. This directional change was rooted in the emerging knowledge that although HFCs have substantially lower Global Warming Potential (GWP) values than their predecessors, they could still contribute 0.28°C-0.52°C to the warming of the Earth’s surface by the end of the century in a “business as usual” scenario. Therefore, it was imperative to look for a new and the fourth generation of refrigerants with low Ozone Depleting Potential (ODP) and low GWP. It is estimated that the Kigali Amendment would limit the climate impact of HFCs to 0.06°C by the end of the century. The search for the fourth generation of refrigerants is still on and the third transition (T3) of refrigerants is yet to officially begin. Hydro-fluoro-olefins (HFOs), refrigerant blends, and even natural refrigerants like ammonia and carbon dioxide (which formed the first generation of refrigerants) are the forerunners – this is why the refrigerant transition is said to be cyclical.

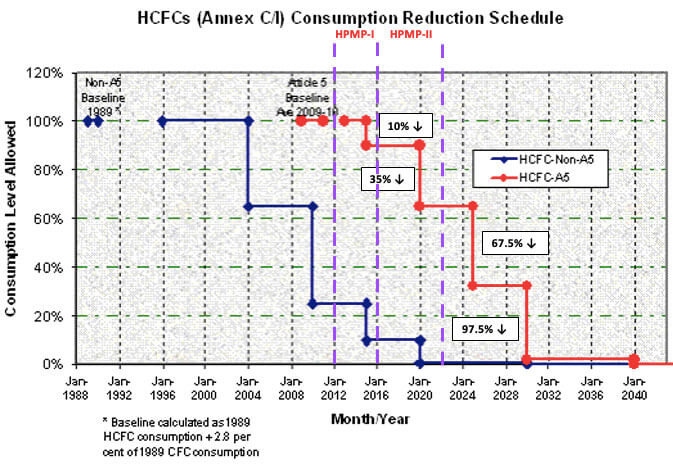

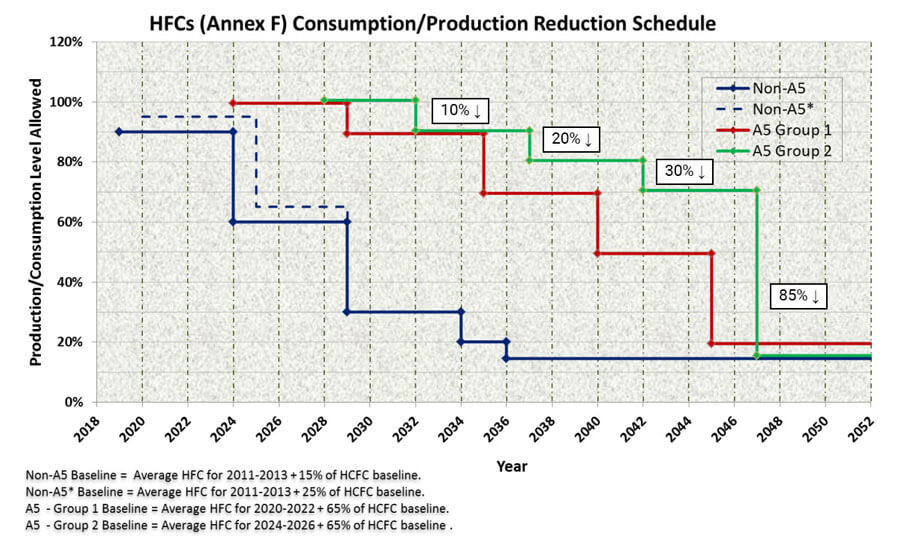

Unlike the Paris Agreement of 2015 wherein the principle of Common but Differentiated Responsibilities acknowledges the different capabilities and differing responsibilities of individual countries to act has become purely theoretical, especially with China’s changing position in the world, it is more effectively enshrined and implemented in the Montreal Protocol. The countries (or Parties as they are called) are classified into 2 categories: Article 5 Parties (comprising nearly 75% of all Parties) with less stringent targets and Non-Article 5 countries (comprising nearly 25% of all Parties) with more stringent targets. Both groups of Parties have binding, time-targeted and measurable commitments. Two of the largest consumers of refrigerants in the world, China and India, are Article 5 Parties.

Article 5 countries, including India, are presently amidst the second refrigerant transition (T2) from HCFCs to HFCs. It can be inferred from Figure 2 that India has agreed to reduce its HCFC production and consumption by 10% in 2015 over the 2009-10 baseline, 35% by 2020, 67.5% by 2025, and 97.5% by 2030 – India can continue to use the remaining 2.5% for service applications until 2040. To achieve this reduction schedule, India is implementing HCFC Phase-out Management Plans (HPMP). HPMP-I, from 2012 to 2016, outdid its target of 10% reduction by 2015 and trained 11,000 service technicians across the country. HPMP-II is currently in progress and aims to phase-out R-22 (an HCFC) from 6 room AC brands in the country by 2022 and train 17,000 service technicians. It is important to note that Article 5 countries have a 10-year leeway as compared to Non-Article 5 countries in their reduction schedules.

The third refrigerant transition from HFCs to the unidentified fourth generation of refrigerants is yet to begin for all Parties as per the constructs of the Kigali Amendment (Figure 3). For this transition, Article 5 countries are divided into two groups – Group 1 with stringent targets and Group 2 with less stringent targets. India with nine other countries constitute Group 2 which has the least stringent target. India will phase down HFCs from 2032 until 2047, 10 years behind Non-Article 5 countries. India will start phasing down HFCs just 2 years after fully transitioning from HCFCs to HFCs in 2030 – this means that the RAC industry will need to undergo transitions consecutively! This presents an opportunity to leapfrog from HCFCs to low-GWP variants of HFCs and natural refrigerants (like R-290), bypassing high-GWP HFCs altogether.

Harmonising Energy Efficiency with the Refrigerant Transition in Refrigeration and Air-conditioning

The answer to the question posed earlier (Why is the Montreal Protocol interested in energy efficiency?) lies in the directional change of the Montreal Protocol that took place at Kigali in 2016. The Protocol will now combat ozone depletion and global warming.

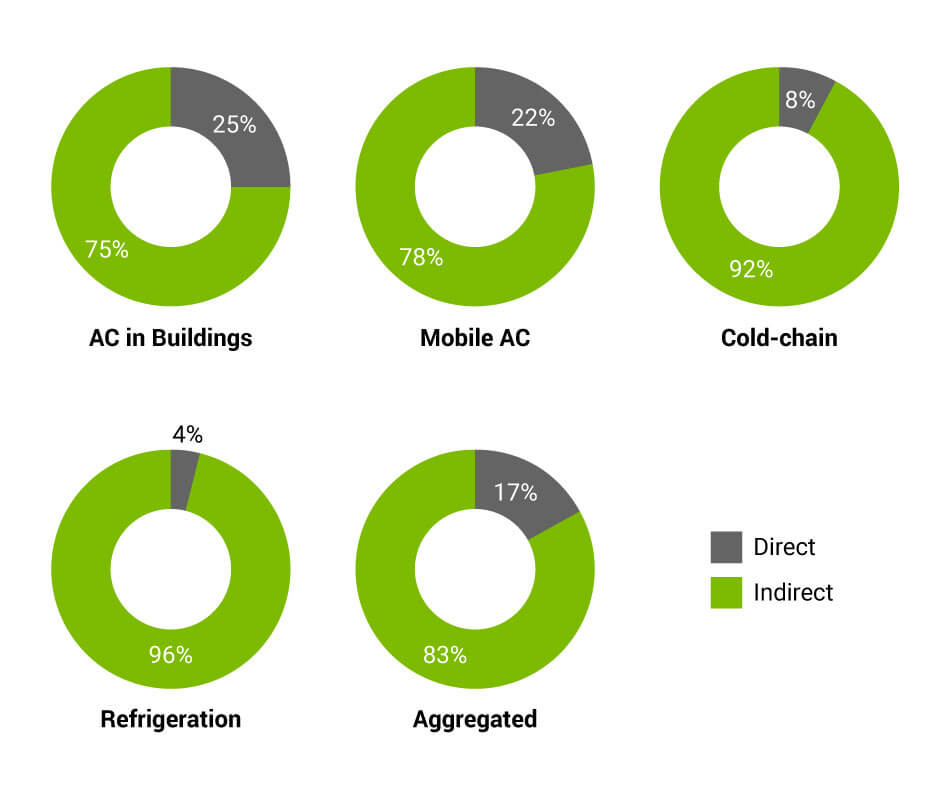

Greenhouse gas (GHG) emissions from refrigeration and air-conditioning are of two types: direct GHG emissions due to the leakage of global warming refrigerants whilst using, servicing, and disposing of cooling appliances; and indirect emissions due to the consumption of carbon-based electricity to run these cooling appliances. Using 2017-18 data, Figure 4 depicts the relative share of direct and indirect GHG emissions – as a rule of thumb, indirect GHG emissions comprise 80% of the total GHG emissions. The answer to the question around the Montreal Protocol’s interest in energy efficiency now reveals itself: it is not possible to meaningfully reduce GHG emissions from cooling without reducing the electricity intensity of cooling since nearly 80% of all GHG emissions from cooling are indirect. Thus, energy efficiency becomes an inevitable component of the future discourse of the Montreal Protocol.

This is a particularly important development for India, considering that India’s cooling demand is latent. Per the India Cooling Action Plan (ICAP) 2019, India’s refrigerant-based cooling demand is projected to grow 9X by 2037-38 over the 2017-18 baseline. This creates a critical window of opportunity to increase the energy efficiency of new cooling equipment whilst transitioning to low-GWP and low-ODP refrigerants for maximised climate benefit.

The Technology and Economic Assessment Panel (TEAP), established in 1990, is the technology and economics advisory body to the Montreal Protocol Parties. If there is a request from a Party, TEAP provides technical information related to alternate cooling technologies. At present, there are three different task forces under TEAP – and one of them is the Energy Efficiency Task Force (EETF). These task forces have senior members from different countries who are experts in the field of energy efficiency and regional economics, and can help in forecasting the market penetration and some potential future alternatives for HCFCs and HFCs.

The latest TEAP report, prepared for MOP32, addresses new developments including best practices, availability, and the cost of energy-efficient RAC and heat pump technologies that can support the implementation of the Kigali Amendment. The report covers:

- Revision of Minimum Energy Performance Standards (MEPS) and Standard & Labelling (S&L)

- Safety standards of low-GWP refrigerants

- Some Not-In-Kind (NIK) cooling technologies

- The role of National Cooling Action Plans (NCAPs)

- Case studies

The Way Forward

It is clear that energy efficiency and the refrigerant transition must go hand in hand. Presently, the Bureau of Energy Efficiency (BEE) addresses energy efficiency through its MEPS and S&L Programme for cooling appliances, whereas the Ozone Cell addresses refrigerant transition through the HPMPs. ‘Eco-labelling’ can help merge energy efficiency and the refrigerant transition into a single index by expanding the focus of the existing S&L programme from only energy consumption, which is responsible for indirect GHG emissions, to also include direct GHG emissions from refrigerant use. The ICAP also recommends that a single eco/environmental label should be used which factors in GWP, ODP, safety, performance, and energy efficiency.

In the short-term, eco-labelling is recommended for room air conditioners. Per the ICAP, 450+ million units of room air conditioners are projected to be installed in India by 2037-38 (as compared to 39 million in 2017-18) – this presents an important opportunity to drive both energy efficiency and more climate-friendly refrigerants in parallel to reduce indirect and direct GHG emissions. While a concerted effort by the government, the civil society, and particularly the industry will be required to realise this new standard, the market is already gearing up in this direction. For example, of EESL’s bulk procurement tender for 100,000 super-efficient RACs, 40% share went to Godrej’s R-290 based RACs; the Global Cooling Prize launched with support from Department of Science and Technology (DST) will reward the cooling solution with 5X less “climate impact” through a combination of both energy efficiency and more climate-friendly refrigerants. The programme could eventually be expanded to a broader set of vapour compression-based space cooling and refrigeration appliances/systems. Eco-labelling will drive the market’s attention towards green refrigerants, and also usher in a new mode of collaborative research and technology transfer opportunities and help India demonstrate leadership in innovative S&L.